Recycling plastic waste into durable goods

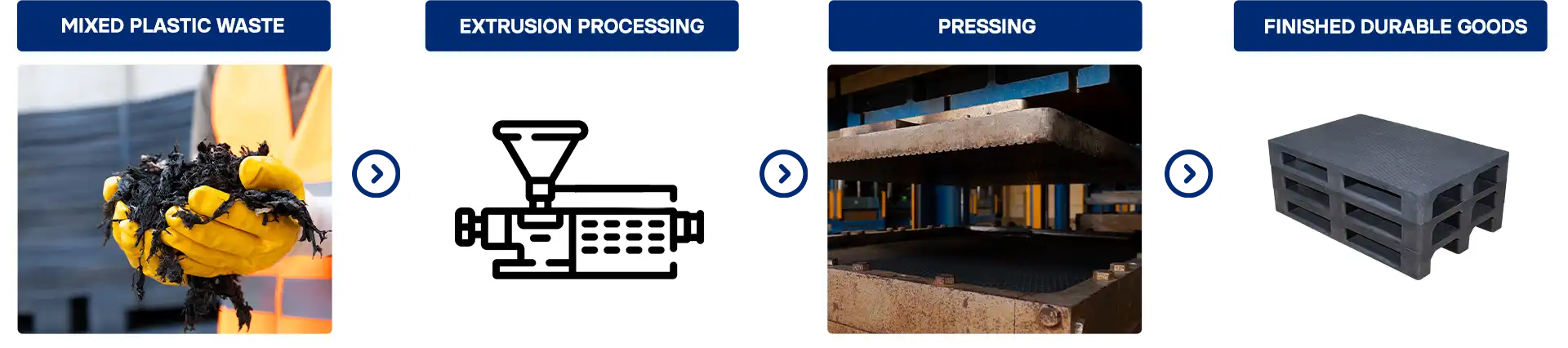

Today, many plastics are either too difficult or economically unviable to recycle, often ending up in incinerators or landfills. At Upsyde, we provide a solution to recycle these challenging plastics and give them a second life. Additionally, we shred damaged or substandard pallets and Ground Protection Mats, reuse the material, and close the loop—promoting true circularity in our production.

Using our manufacturing process, we transform plastic waste into durable products such as pallets, ground protection mats, and heavy-duty mats. These sustainable goods are reusable, made with over 95% recycled materials, and are 100% recyclable at the end of their lifespan.

Which plastics can we recycle?