Plastic waste: what if there’s another way to go?

Currently, much of plastic considered hard-to-recycle ends up in landfills or energy recovery. With our innovative waste-to-parts technology, we demonstrate there is a way – our circular goods are made from 100% recycled plastic.

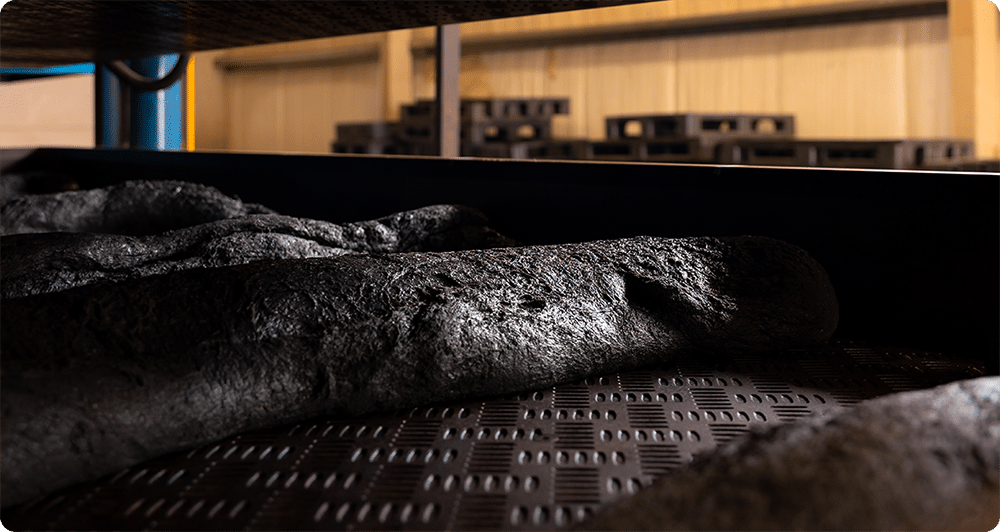

Those are potential sources we use to produce our circular goods: